Pulse - Human Centered Design Manufacturing

Summary

Aerospace Manufacturing represents a decades old practice of hard and true methods of building products. The vast assembly and intensive nature of installation requires an accurate base of knowledge that is both physical and digital. Pulse was meant to bridge these legacy methods into one human centered design application that could enable mechanics to efficiently and accurately build. A major element in the manufacturing ecosystem are 2 problems that Pulse was solving. There’s not visibility into the pace of production or problems until the next day. Job data isn't entered accurately in real-time. People can’t call for help from their work location and must travel to enter job progress into the system. At times, they wait for computers and enter at breaks or end of shift. As a result, we have a stale view of factory performance & work on yesterday’s problems.

My Role

I was the was a Senior Product Designer supporting a US based team of a Principal Designer, a Junior Designer to prototype out concepts to meet the capabilities that aligned to the Pulse Product Roadmap

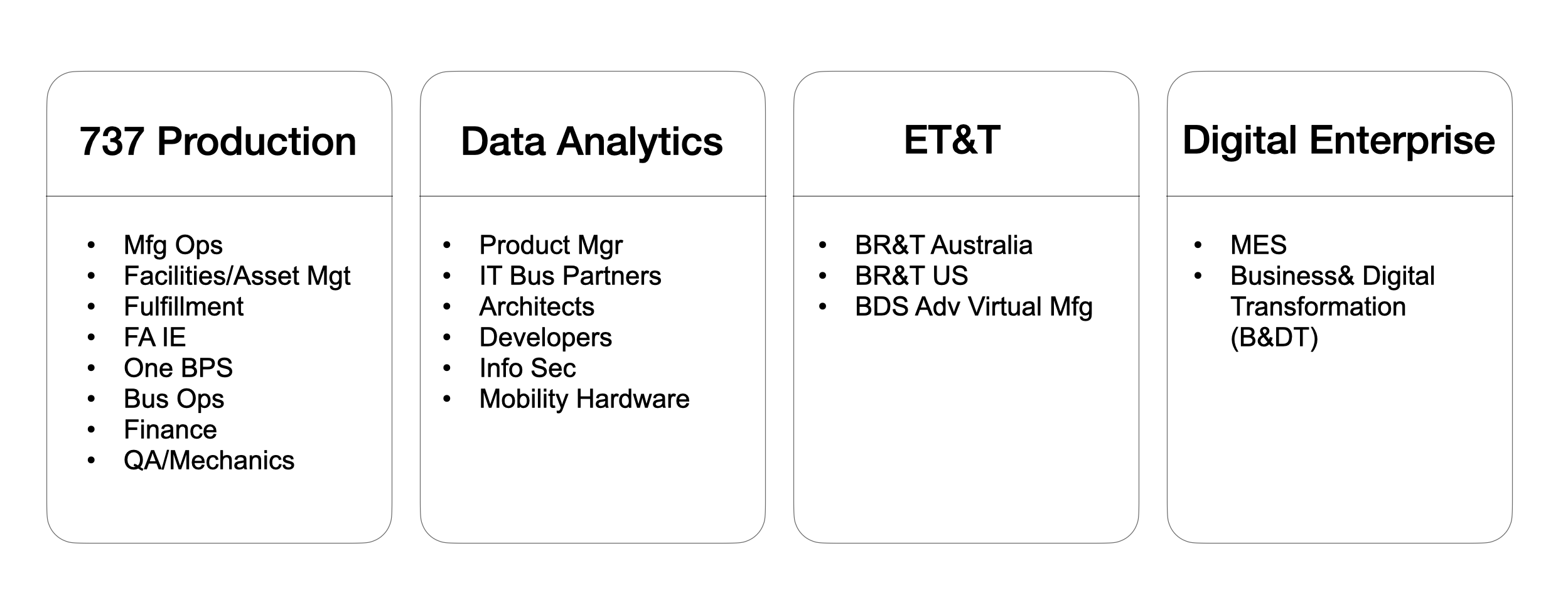

Cross Functional Team Engagement

User Research

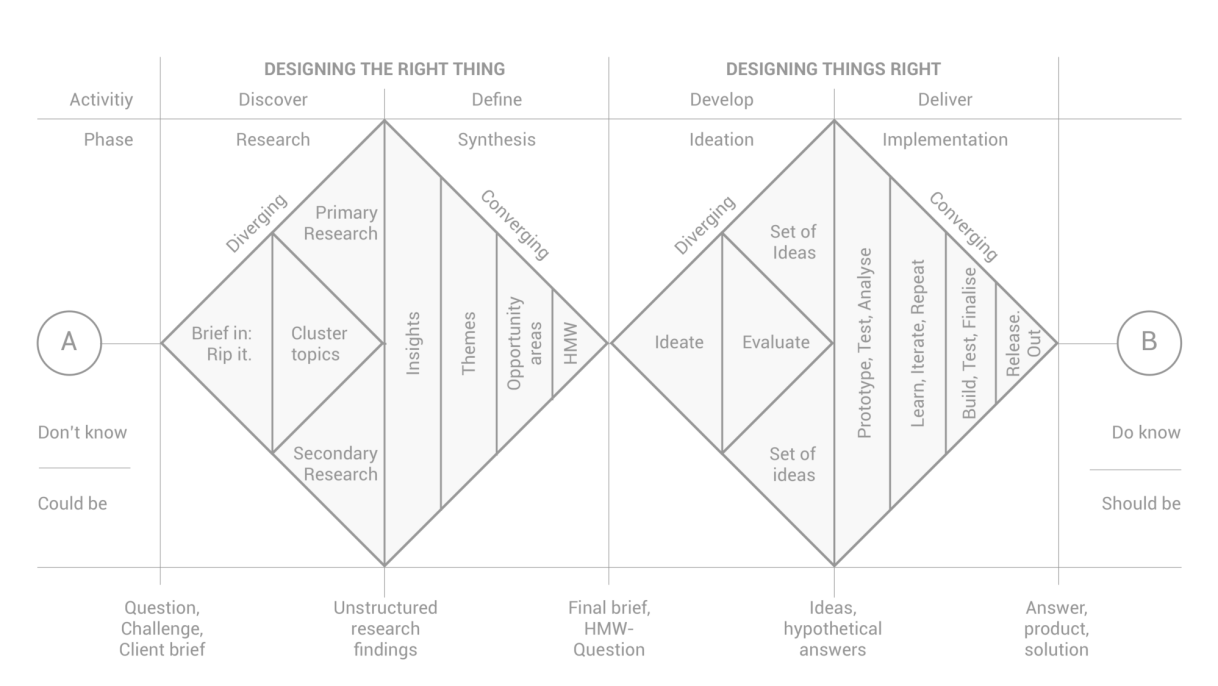

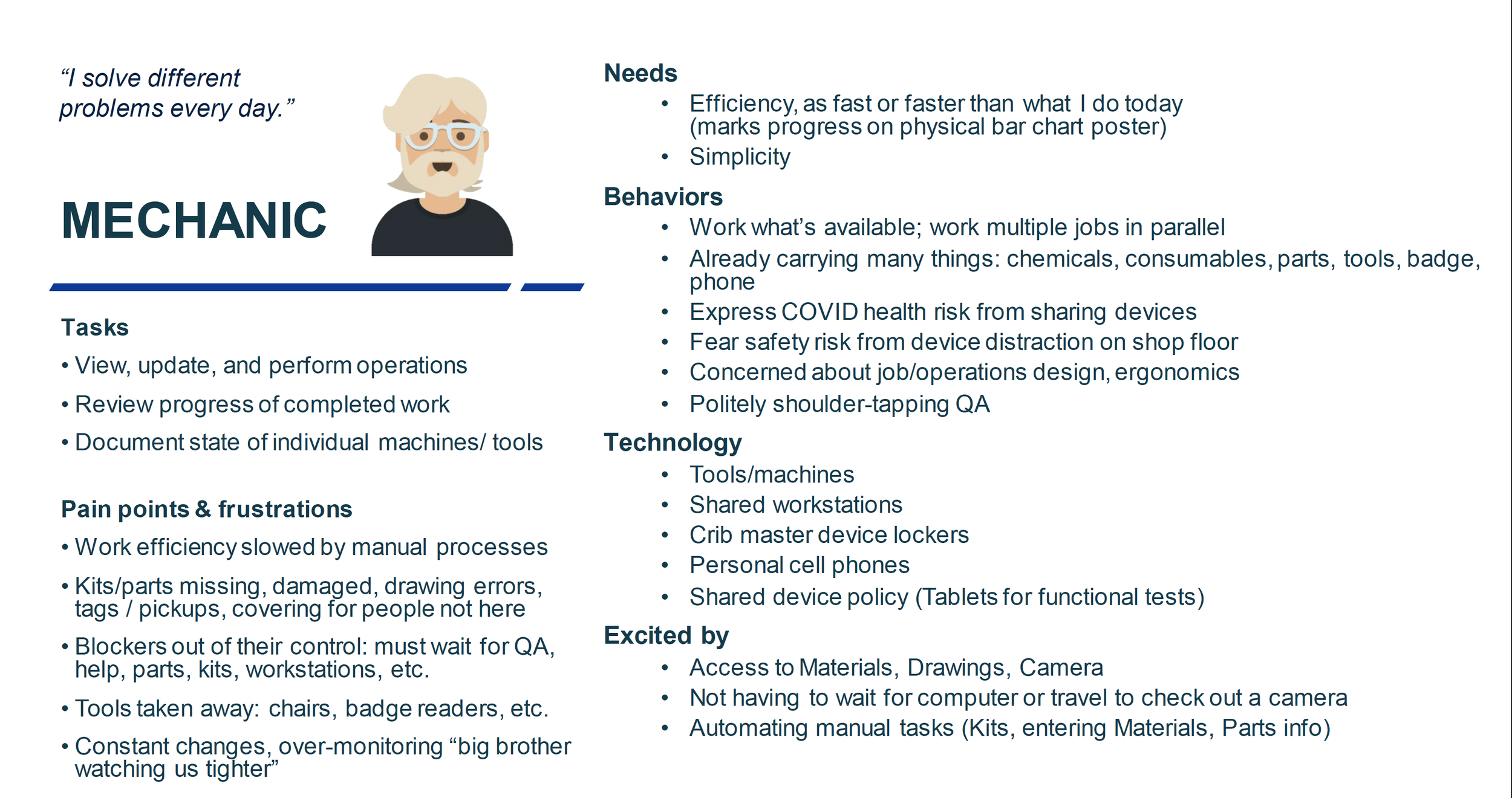

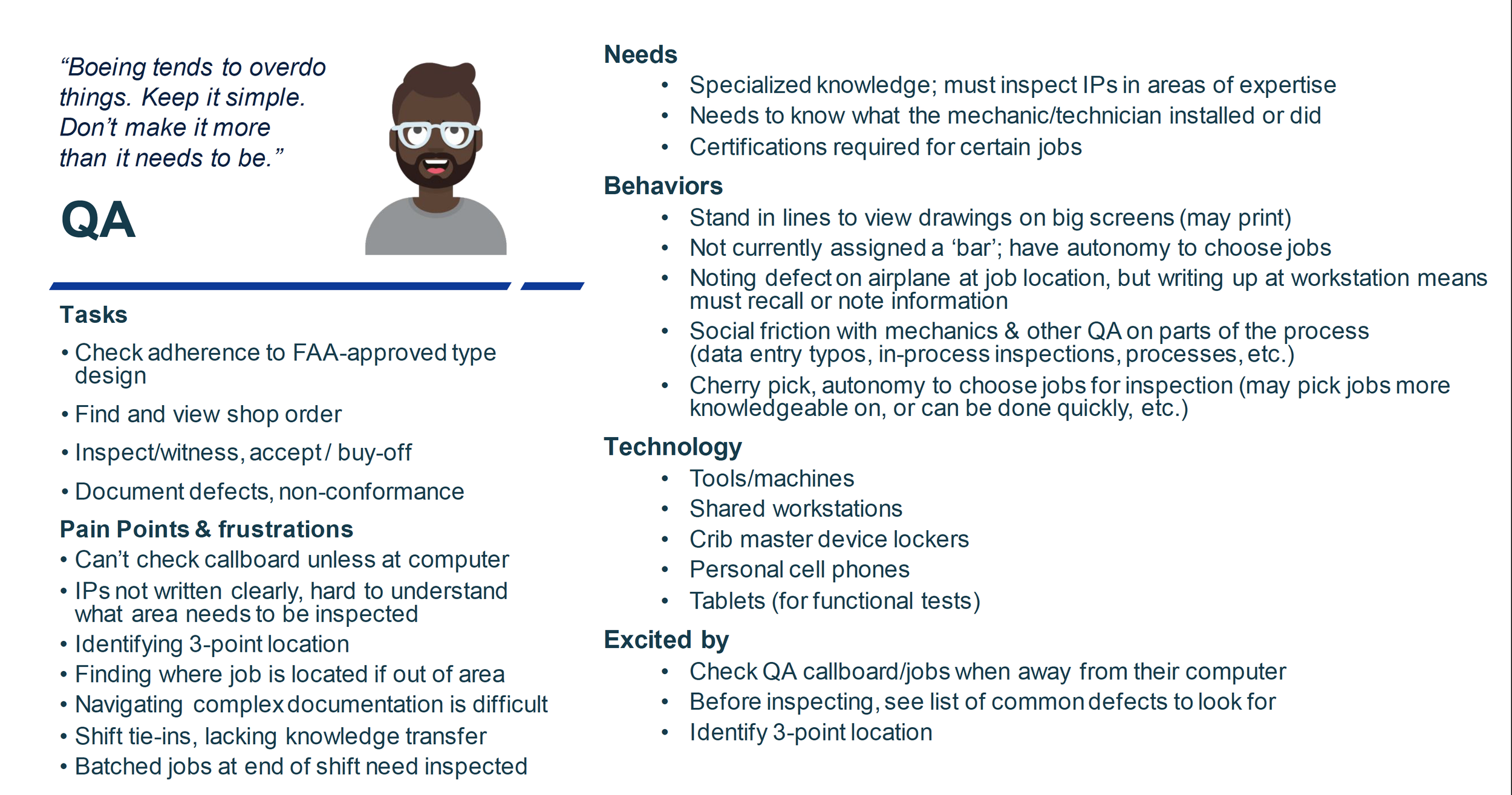

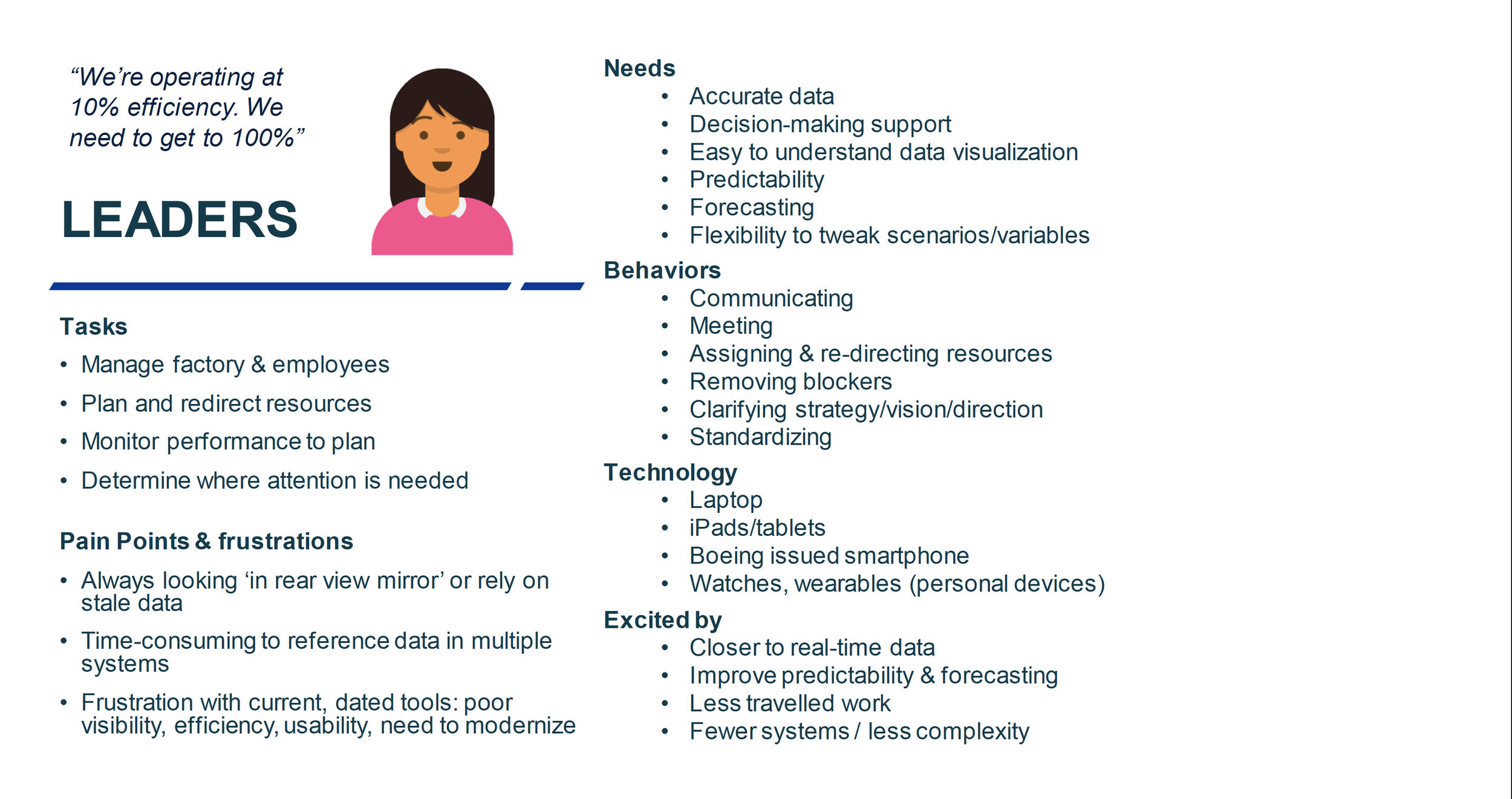

The User Research team conducted an in depth Discovery & Framing approach to understand the multiple avenues of impact that Pulse could take on. During the initial discovery phase, 40+ interviews were conducted with the manufacturing teams comprising of mechanics and quality assurance inspectors. The goal of this contextual inquiry, was to get an inner working and understanding of the current work flow and eco system to their standard work. A service blueprint map was drawn up to start developing a user journey that highlights a users emotional engagement with manufacturing applications from initial start to ending, touch points, and back end system architecture.

From that activity assumption gathering began where the team started identifying and documenting hypothesis we had about users needs and wants. User Personas were also archetypes to tangibly identify the tasks, pain points and frustrations, needs, behaviours, technology and areas of excitement to help tangibly map some areas of opportunity. A user journey map was also created to digitise what the future ideal experience might look like.

User Personas

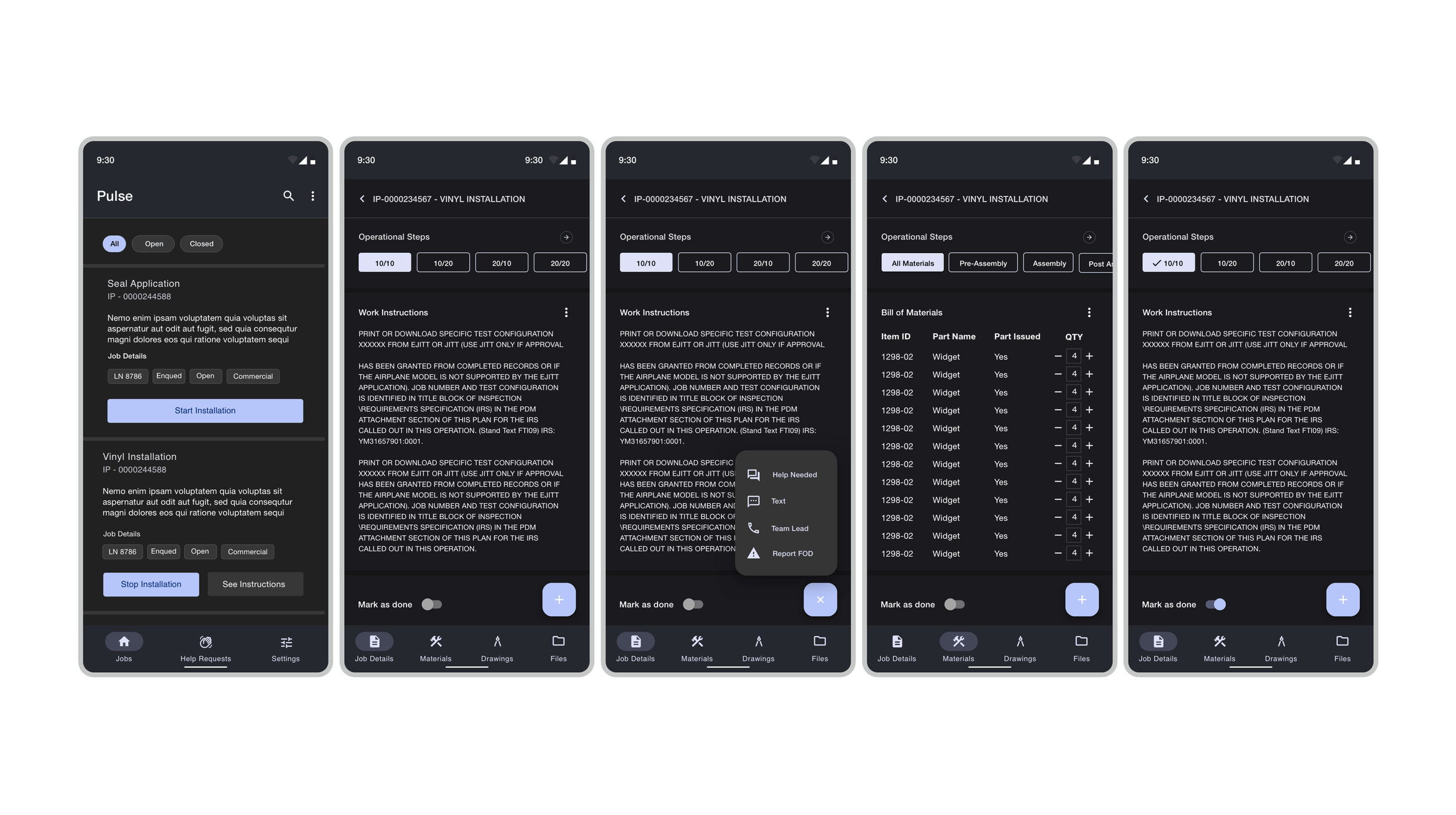

MVP - Starting Work/Completing Individual Steps

From an extensive Risk/Impact Generation workshop where the highest impact, low risk and vice versa actions the product team can take on, a final down selection was chosen. The first experience to be developed would the core experience of Starting Work and Completing Installation steps. This experience would focus around the Mechanics and Quality Assurance Inspectors daily statement of work. This meant finding the right interaction method to showcase how to individually launch a job. The tertiary action was for a Mechanic or Quality Assurance inspector to stamp off operational steps within an installation plan.

Responsive Design

It was highly important to consider responsive design in all projects and especially Pulse. This will help accomodate various monitor and viewport and prevenitng excessive scrolling. Documentation both internally and externally was reviewed to ensure a solid baseline grid system. The end goal being a device agnostic experience that would snap to various screen sizes. This meant testing on the most common devices utilised in production. Initially the Samsung S8 was the first go-to device chosen for Pulse, hence the original design. However the induction of Apple and iOS devices changed the direction of the Product Design to include that device.

Material Design

Accessibility Considerations

Design Studios

An insightful part of the design process for the progression of Pulse considering its engineering complexity were proactively running studio sessions with various cross functional partners and users. There was an important focus on psychological safety to ensure everyone felt validated and heard. They were set up monthly sessions where they could share their perspectives from the hats of technical feasibility (development perspective), user practicality (mechanics/quality assurance), viability (product teams) and usability (with other designers).

They were setup in a way to start with a '“How Might We” question focusing on what capability we might design to provide the solution to an outcome we’re trying to solve. 2 x 15 minute sketch sessions were practised where everyone could either describe or draw their ideas out (whilst a good ambient Spotify playlist was playing). Afterwards I would collect those artefacts, digitise them and reference them during the wireframe creations to understand intent and right size my design approaches.

Initial Design

At the start being closest to the User Research near the Factory, the US design team had sprinted ahead and created their initial prototype for the Samsung S8 using a mix of interaction patterns and concepts before I became the designated Prototyping lead. The below was their first iteration.

Initial Concept Usability

The bespoke nature of some of the User Experience components and behaviours made it challenging to interpret what the interaction next step might be. Furthermore a vertical scroll heavy experience would make it challenging with larger installation plan jobs with dozens of operational steps, thus a new interaction design would need to be considered.

Updated Design

Usability Feedback

Transitioning the design from a vertical scroll to horizontal experience also optimised the viewport to be agnostic across devices being utilized with manufacturing teams. There were some incremental updates of interest, such accessing the additional page content from a dropdown to tabs for easier discoverability which were implemented over the course of the roadmap. There also was an interest in a future dark mode state with considerations to accessibility and also research into a more accessible text sizes.

Iterative Design Approach

Next Milestone - Help Needed

A major challenge on the factory were delays to production due to interruptions, rework or incorrect parts in their kits. This resulted in them being held until they could have the interruption be sorted (usually a travelled work mechanic completing a previous job or another mechanic in the critical path build sequence also being held). This made it difficult to accurately track installation plan time and as production flows and new sequences came into the production system (eg, increased production) . Thus this was the next major milestone on the roadmap generated from the risk/impact generation activity and Outcome roadmap

Help Needed - Initial Prototype

The main things a mechanic would need: down selecting what their issue is, then selecting the specific parts that they needed help with (eg kit shortage) and then submitting that request. I created a 2 step process and utilised a variety methods such as a carousal based design to optimise screen real estate. The first version is below..

Usability Feedback

There was a consistent theme around a preference for a more hybrid vertical and horizontal experience than a heavy focus on either interaction pattern. Some additional capabilities were needing to be explored such as taking a photo were further discovered. There was also an interest in clarifying the steps were intended to be 3 rather than 2. All of these learns went into the next round of prototype.

Help Needed Update

This final format tested really well with users who were able to utilize both the slide up capability and horizontal scroll as needed. The enhanced and broadened UI space from not needing to crop for the browser experience also helped gain the additional real estate to optimise the user experience.

Research Guided Design

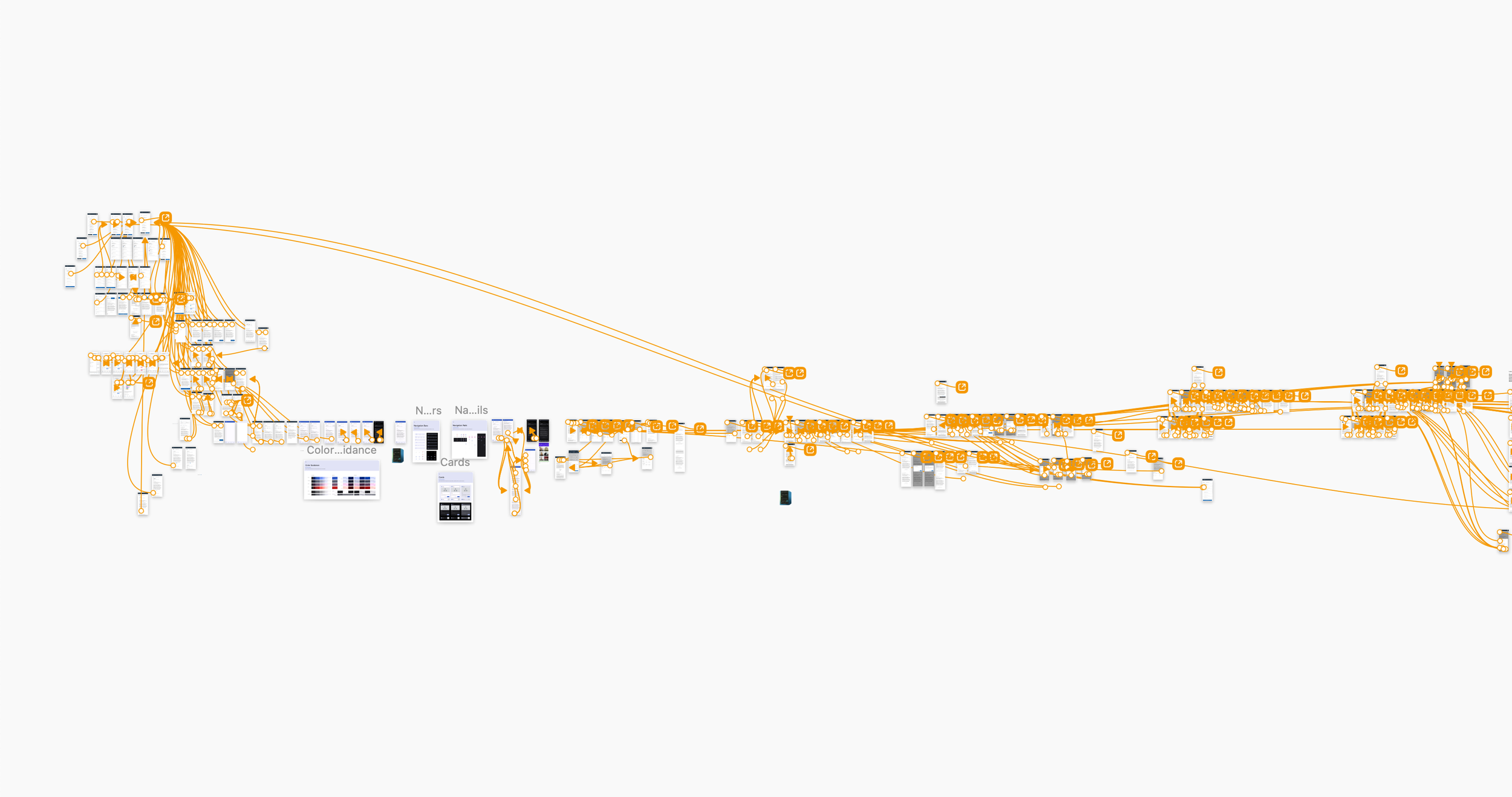

The core design was narrowed down based from usability after the main concept was drawn out and design studios iteratively conducted to understand best layout. 6-8 users composed of the direct or tertiary shadow users were tested to understand intuitiveness and how it stacked against the core heuristics. Feedback was around keeping visuals lean and providing intuitive ways of discovering and utilising information such as through horizontal and vertical card patterns. Research provided proper guidance on the best visuals, benchmarking against industry standards and providing the nuanced manufacturing information that would be relevant to gain insights. This shows the design evolution from broad to narrow with bi-monthly usability studies and stakeholder reviews to showcase progress and document learnings. The core design layout being narrowed in on show in the final visual of vertical layout with horizontal controls.

Dev/Design Pairing

As Pulse reached its launch, regular implementation sessions were standardised to ensure the designs weren’t introducing beyond scope technical debt and also to help pixel perfection. This meant ensuring complete alignment to Material Design standards and to also evaluate its evolution. At the start of pulse, Material Design 2 was the referenced system, however towards the latter end of the initial MVP Material 3 had been launched. This evolved design had through research updated its design standards to simplify and also iterate the look and feel of common components. As a result when opportunity arose those elements were incorporated into the Pulse Design.

Shipped Core Product Design

The core Product Design was finalised to be the below User Experience. The default mode established from users was that a dark mode was optimal considering the darker environments of manufacturing environments and made it more ergonomic to interact with over time. The design also implemented such evolved Material 3 elements such as the emphasis from rounded off chips to more soft bevel designs and update to Floating Action Buttons to also reflect this evolution.

Outcome

Pulse is now being utilised and rolled out into the Airplane Production ecosystem and gradually rolled out across the wide array of products Boeing builds. Pulse has enabled Manufacturing teams to be more mobile and have more value added time onto the airplane they are building with a user centered design approach to incrementally add updates.. In the next iteration the focus is development of a desktop versioning of Pulse and also of Call Boards where teams can see and track progress and block points. The data ingested has also helped the manufacturing engineering teams to update and provide more agile methods across jobs to optimise production builds and find the fastest time across the critical path build sequence.